Global Solution Provider of

MEASURING and PROCESS

CONTROL EQUIPMENT

for

OPTICAL FIBER MANUFACTURING

Making Sure To Achieve Excellence In

Manufacturing Of Optical Fibers!

OCTech has been in business of providing solutions to customers in fiber industry for over 20 years, all over the world.

Specialized measurement and process control equipment is developed on the basis of

process knowledge as result of more than 30 year long career in fiber optics.

OCTech solutions are covering a range of tools to be used in production process of optical fibers and preforms,

with fabrication of special optical fibers as prime application field.

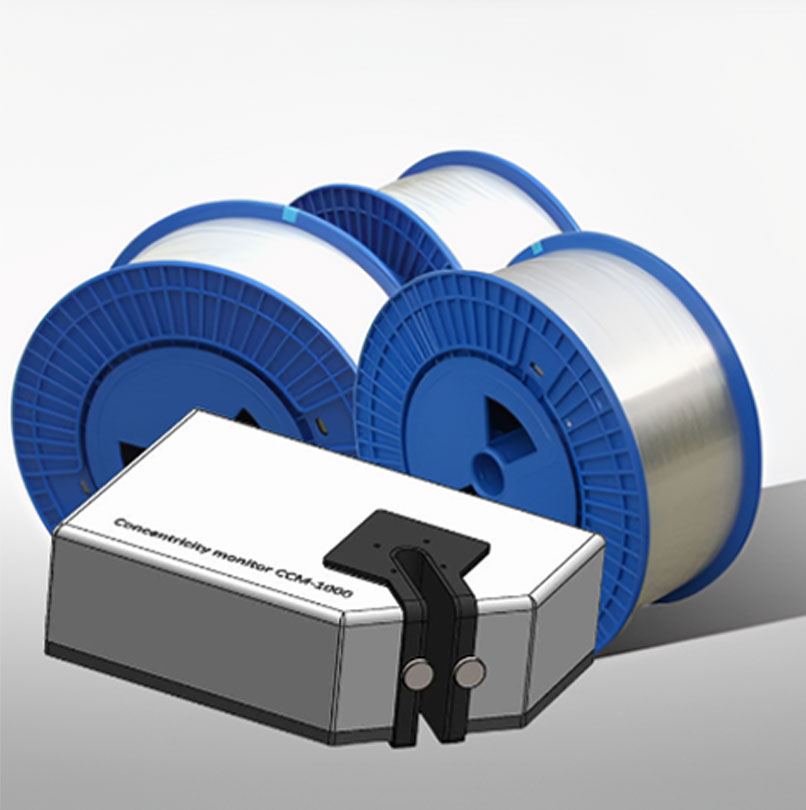

CCM1000

Fiber coating concentricy monitors

CCM1000 series monitors measure and display fiber coating concentricity errors during the fiber drawing process, using two fast CCD cameras to capture and analyse scattering patterns of the light beams projected on fiber by two laser diodes, positioned at 90° to each other. Fast algorithm permits real time evaluation of coating to fiber non-concentricity, showing also the angle at which the maximum of non-concentricity occurs. With up to 140 frames per second camera speed, CCM can replace traditionally used optical beam and screen concentricity monitor and provide relevant process information at draw line speeds over 2500 m/min.

WinP102

Preform analyzer upgrades

WinP10X is a family of software solutions, permitting to operate YORK (PK) preform refractive profile analyzers from Windows environment, replacing obsolete Hewlett-Packard instrument controllers. With full upgrade to vertical position, with automatic preform feed anrotation, the YORK instruments obtain new functionality that makes their performance comparable to next generation of preform analyzers. These solutions are ideal for research organizations and small fiber labs due to lower investment and more suitable interface.

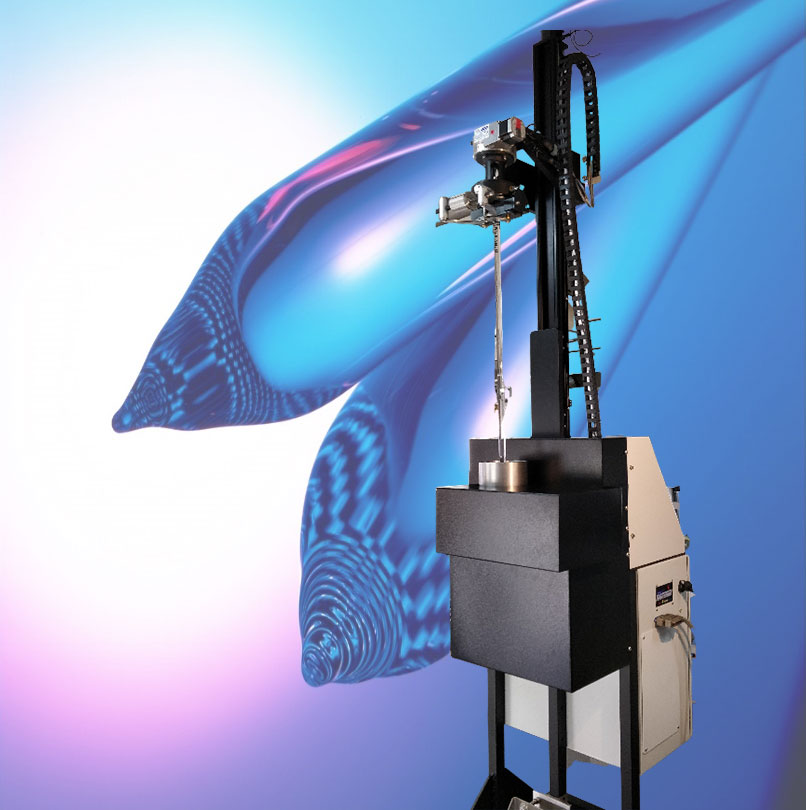

WOF

Winder For Optical Fibers

WOF is a small. portable, optical fiber take-up winder, suitable for winding fibers fed by a capstan or from a pay-off with back tension. Winding speed is from a few meter per minute to 100 m/min. Winding pitch and winding force can be set on WOF through a set of potentiometers, while wound length can be set through the microprocessor controller. WOF can detect fiber brake and stops winding when there is no signal from an encoder-equipped guiding pulley. WOF is ideally suited for special optical fiber makers on small draw towers or in other fiber rewinding operations. WOF accepts standard fiber optic 25 and 50 km spools.

POL

Preform Polariscope

POL polariscope is an essential tool in optical fiber preform production. It provides visual analysis of core preforms or rods. It helps detect bubbles, inclusions, cracks, strain regions and other defects in glass structure. Defects are detected by inserting preform between two crossed polarization filters and placing the whole assembly into a white light beam. Sturdy mechanical construction ensures proper preform fixing, preventing vibrations and damage, as well as touch-free handling. Built-in magnifying lens and gradation on the guide rail enable exact positioning of defects relative to a chosen reference point, for process database as a reference to drawn fiber.

STR

MCF Stacking rig

STR stacking rig is an accessory, used in assembly of MCF or PCF optical fiber preforms. The rig permits capillaries or rods to be arranged into octagonal stacks by providing a set of suitably-shaped supports with precise positioning mechanism. After stacking the inner preform elements, a jacketing tube can be added to the assembly. Finished assembly is then taken to glass working lathe for sealing. STR is adjustable in length and can accommodate stack with length up to 1 meter (or longer if required). A stand with holders for different size elements is supplied with STR as accessory, helping users to better organize assembly work